Retention product storage adapted to your company's environment !

Publié le 2021-07-09

The installation of retention products significantly reduces workplace pollution, especially in industrial or logistical environments, and of course in the environment in general. Retention storage involves implementing a system to collect potential leaks from containers holding hazardous liquids, such as pollutants, hydrocarbons, oils, and chemicals. Companies use retention storage to ensure the protection of their employees’ work environment and the preservation of the ozone layer. There are strict rules to follow depending on the type or volume of the product, but they are not always easy to apply.

Retention products are made from various raw materials : flexible PVC, polypropylene, polyethylene, stainless steel, painted steel, galvanized steel, polyester, and fiberglass, etc. They come in different sizes, capable of holding one, two, four, or even eight barrels, depending on the products.

Smaller models are designed for jugs, bottles, and tanks.

The retention systems to be deployed must be carefully planned and organized based on the nature of the stored products and the company’s environment.

Ask Yourself the Right Questions:

What is the level of hazard? What volumes need to be stored? Where will they be stored? And what surface area is covered by the containers (tanks, barrels, basins, etc.)?

The risks of poor organization with hazardous products can result in faulty storage with serious consequences, such as dangerous chemical reactions, significant releases of toxic substances, or even explosions or fires, poisoning, slips, or injuries.

Many factors play a role in storage safety:

- The quantity of stored products,

- The presence of volatile, flammable, or incompatible products or materials,

- Ventilation,

- The securing of packaging,

- The stability of packaging materials against temperature variations and radiation,

- The warehouse must be arranged to secure the entire area, and proper ventilation must be ensured. These measures are primarily aimed at protecting the company's staff and the environment. Regulated storage ensures environmental protection as products are not discharged into nature when companies no longer need them.

Thus, it is absolutely essential to properly protect hazardous liquids and other specific products by storing them in suitable materials under the best conditions to avoid any risk of accidents.

Here are various retention and safety products from Actiflip to minimize risks:

- Retention pallet for storage rack,

- Metal retention platform,

- Plastic retention basins,

- Metal retention basins,

- Retention shelving,

- Absorbent rolls and sheets,

- Intervention kit,

- Grating platforms,

- Multi-risk and fireproof safety cabinet,

- Secure and meshed Activance shelving,

- Lightweight retention shelving,

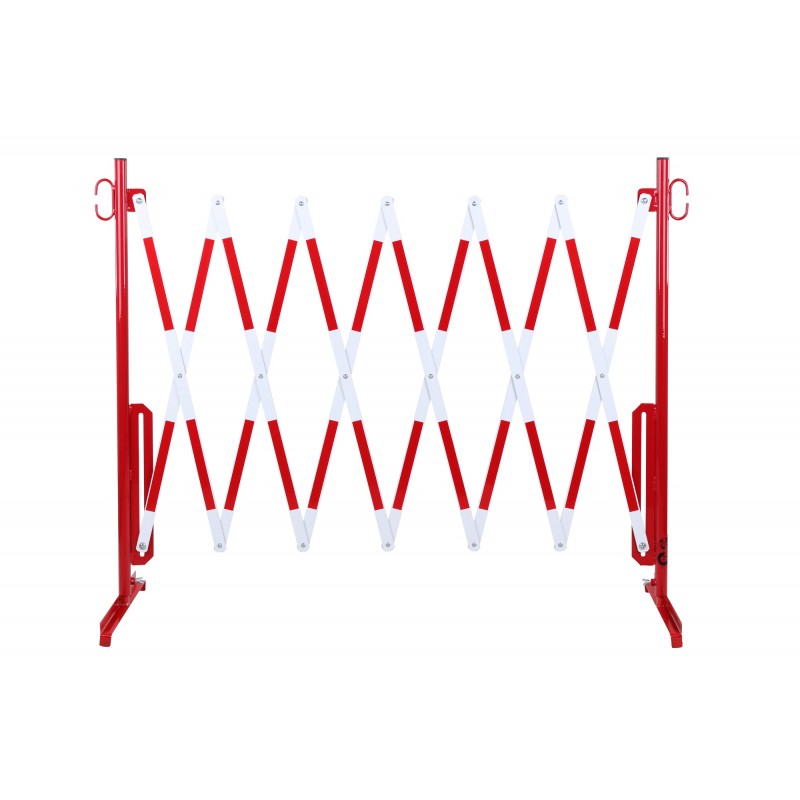

- Expandable barrier.

We recommend our best products to achieve satisfactory results

The Importance of Shelving:

Shelving must be made of mechanically and chemically resistant materials. Effective stabilization prevents tipping, and spacing must be adapted for the circulation of people or handling equipment.

- Metal Retention Platform: Our metal retention platform is the recommended solution for retention storage of solvent products and hydrocarbons. Its hot-dip galvanized steel composition ensures excellent durability and strength while complying with ISO 1461 standards (Metallic coatings — Hot-dip galvanized coatings on ferrous materials — Gravimetric determination of the mass per unit area). As stated on "www.iso.org"

- Secure and Meshed Shelving: Activance meshed shelving provides an effective solution for safely storing your products in industrial environments. Semi-heavy-duty type, its 350 kg per level load capacity allows for both reliable and optimized storage. You can choose a 2 or 3-level shelving option. Its metal mesh comes with a double-leaf lockable door.

- Lightweight Retention Shelving: Actiflip lightweight retention shelving is designed for storing small chemical, pollutant, and non-corrosive containers. Its three different shelf types and high modularity make it an excellent storage tool suitable for any storage space configuration.

- Grating Platforms: With integrated edge reinforcements and hot-dip galvanization, our grating platforms ensure optimal resistance and stability. They are designed to meet safety and sprinkler fire prevention standards.

Safety cabinets include retention shelving. They are recommended for storing flammable products.

- Multi-risk and Fireproof Safety Cabinet: Our multi-risk and fireproof safety cabinets with insulated walls are ideal for safely storing flammable and corrosive products. Highly modular, they are available in a wide range of dimensions and options.

- Retention Shelf: This retention shelving is designed for storing pollutants on 3 levels with a load capacity of up to 320 kg per level. Each level is equipped with a flat iron to prevent items from falling. The shelving comes with galvanized steel retention basins.

- Retention Pallet for Storage Rack: Practical for the retention storage of hydrocarbons, as well as solvent and non-acidic products on pallet racks. Its steel composition and hot-dip galvanized finish make it a reliable and durable tool for the safe storage of hazardous products.

- Metal Retention Basin: Ideal for storing hydrocarbons and solvent, non-acidic products in barrels. Its hot-dip galvanized finish ensures excellent durability and strength. It can be used both indoors and outdoors and is available in 5 sizes for a capacity of one to four 220-liter barrels. The retention basin is designed to support various tanks containing hazardous or pollutant products. Its purpose is to protect the environment, the workspace, and employees.

- Plastic Retention Basins: Protect from hazardous and chemical products, hydrocarbons, corrosive, and non-solvent substances. Made from polyethylene, also available in recycled versions, these basins are an economical and eco-friendly solution. They are lightweight, easy to maintain (rust-free), and available for 1.2 or 4 barrels of 220 liters. Polyethylene is advantageous because it is corrosion-resistant, chemically inert to many substances, rigid, and durable. They can be used indoors and outdoors and are designed for intensive use and weather resistance.

- Expandable Barrier: The expandable barriers are made of flat steel and are suitable for indoor and outdoor use. They measure 3600 mm in length, 300 mm in width, 1050 mm in height, and weigh 13.8 kg. Additionally, the red and white colors are highly visible, making them ideal for ensuring safety.

Different warning or prohibition signs should be prominently displayed in the storage area, such as no smoking signs. It is recommended to arrange the area with non-flammable and impermeable flooring, as well as non-flammable walls. The room should also be equipped with a fire prevention system, possibly with a nearby water source and fire extinguishers.

- Absorbent Rolls and Sheets: This solution allows for cleaning liquid spills, with high absorption capacity (80L per roll). It can be used on workbenches and in laboratories as a protective "mat." Pre-cut sheets (50 cm x 40 cm).

- Intervention Kit: Ideal for responding to flooded or high-risk areas. Maintenance kit: 48 sheets (50 x 40 cm); Hydrocarbon and chemical kit: 32 sheets (50 x 40 cm) and safety goggles for the chemical kit. All kits include: 3 short booms (1.2 m length and 7.5 cm diameter); 5 waste bags (46x90 cm with 5 clamps); 1 instruction sheet; 1 category identification box; 1 pair of gloves.

Finally, here are some organizational tips to optimize safety in your professional spaces:

Finally, here are some organizational tips to optimize safety in your professional spaces:

- Restrict storage access to trained and authorized personnel only,

- Implement storage, organization, and usage rules,

- Also establish a "first in, first out" unloading rule,

- Prohibit cluttering of access ways, exits, and emergency equipment,

- Do not store incompatible products side by side. Calculate the volume of liquid products that can be stored relative to the available space and necessary arrangements.

Now you have all the keys to securely protect your staff, premises, and products in the safest way possible!

Actiflip is pleased to assist you in organizing your environment, protecting your employees, and providing advice!

Consulting a professional maximizes efficiency and reduces unnecessary costs!

Actiflip is a network of experts specializing in professional space organization. A local network spanning the entire territory to advise, design, and evaluate your project for free.

- Publié dans

- Logistics and Warehousing

COMMENTAIRES

Aucun commentaire pour le moment.